Product Description

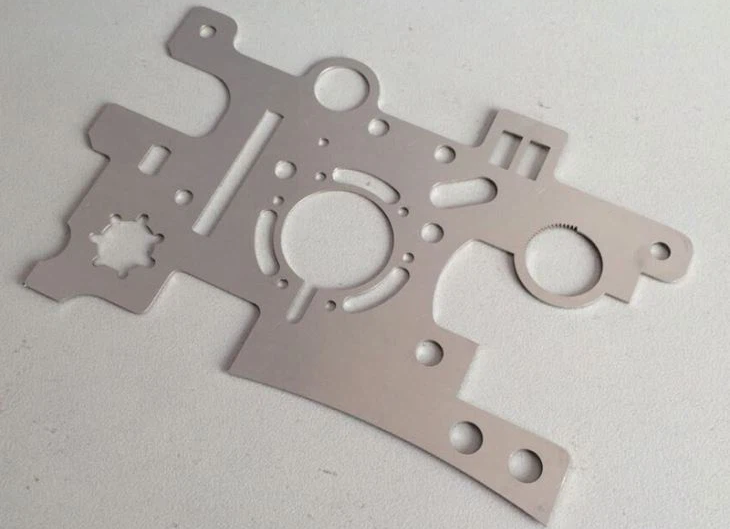

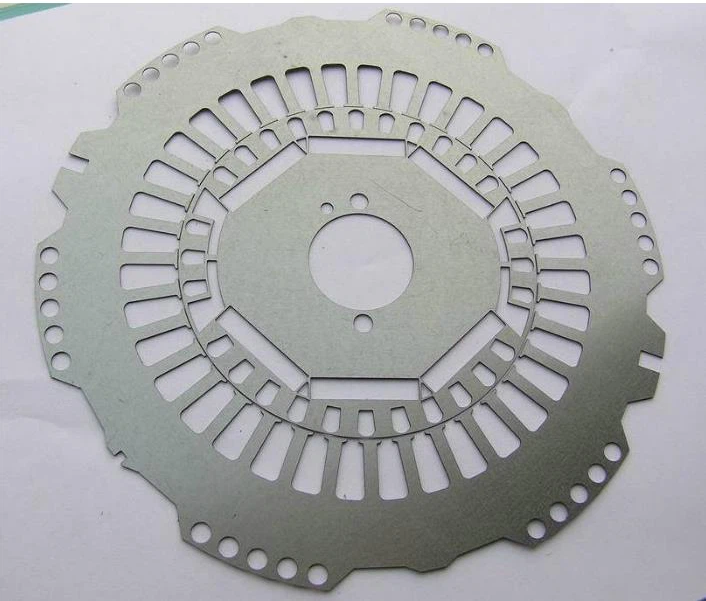

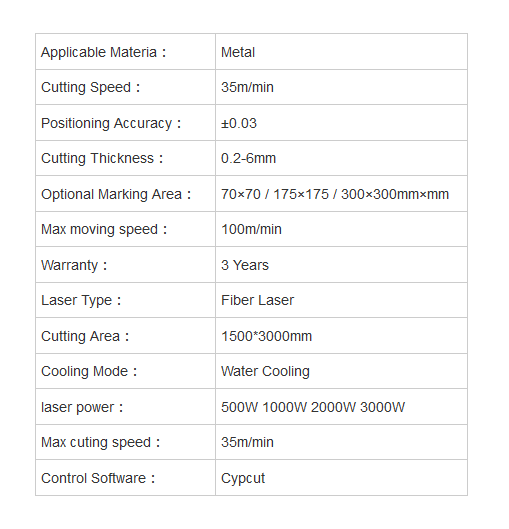

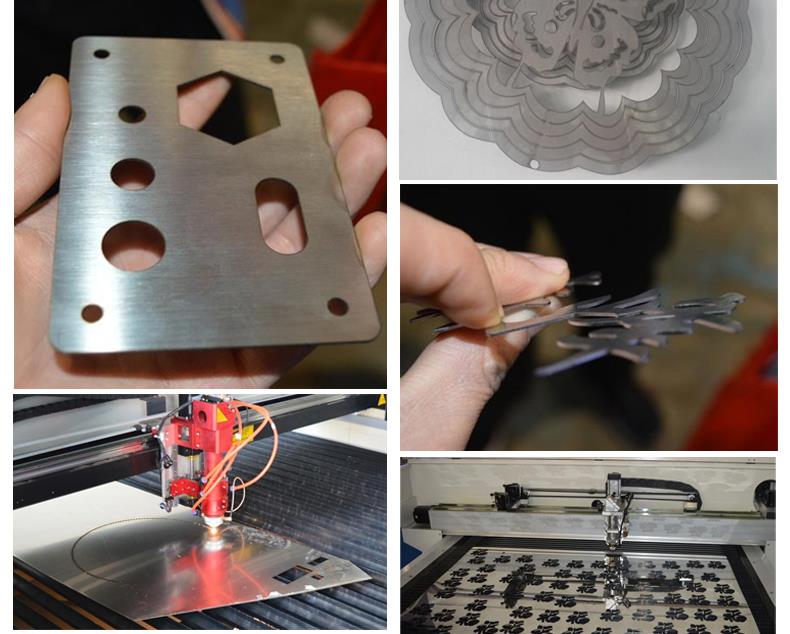

This fiber laser metal cutter series adopted the fastest and cleanest way to cut metals like steel (stainless, mild, galvanized, mirror), copper, bronze, aluminum and more.

1. Excellent path quality: The laser cutter has a smaller laser dot, high work efficiency, high quality.

2. High cutting speed: The cutting laser cutting speed is 2-3 times faster than the same power CO2 laser cutting machine.

3. Stable running: cutting laser stainless steel adopts top-world import fiber lasers; stable performance; key parts can reach up to 100,000 hours of work.

4. High efficiency for photoelectric conversion: bulk CNC cutting lasers for metals compare with CO2 laser cutting machines; fiber laser cutting machines have three times the photoelectric conversion efficiency.

5. Low cost: high-quality laser cutting service with CE/FDA saves energy and protects the environment. The photoelectric conversion rate is up to 25–30%. Low electric power consumption; it is only about 20%–30% of a traditional CO2 laser cutting machine.

6. Low maintenance: CNC cutting laser machines, fiber line transmission, no need for the reflect lens, lowers the maintenance cost.

7. Easy operations: CNC cutting laser system, fiber line transmission, no adjustment of optical path needed.

Applications