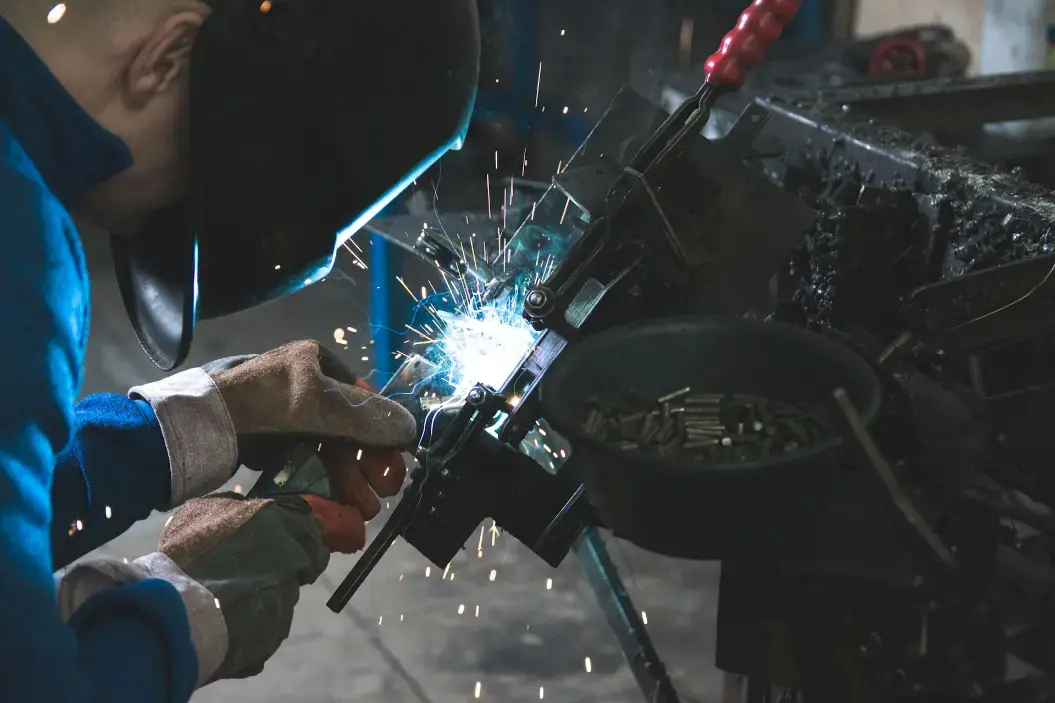

Laser welding is a process that uses a specially focused laser beam to weld metallic or polymeric materials together.

The joining process can also be performed with the use of a wire to join materials that are difficult to weld. All metallic materials that are typically welded conventionally can also usually be welded with a laser. There are three different types of laser welding: conduction, keyhole, and wobbling.

Welding is usually used on metals and thermoplastics, but it can also be used on wood. The completed welded joint may be referred to as a weldment. Some of the fields of application are naval, automotive and aerospace.

Welding

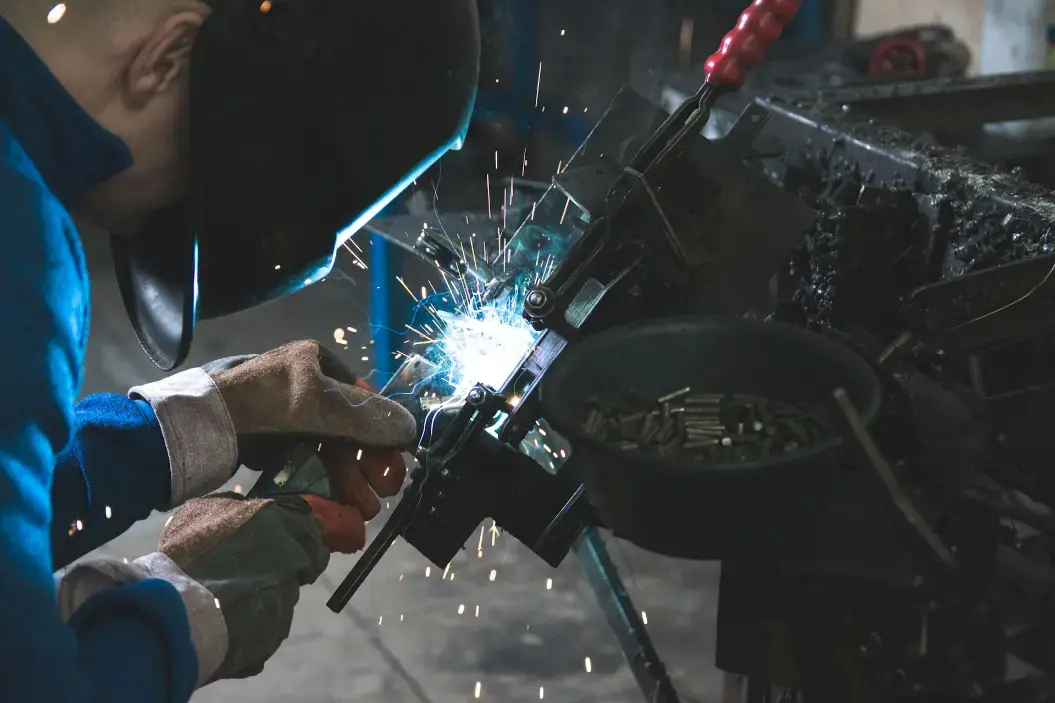

Laser welding is a process that uses a specially focused laser beam to weld metallic or polymeric materials together.

The joining process can also be performed with the use of a wire to join materials that are difficult to weld. All metallic materials that are typically welded conventionally can also usually be welded with a laser. There are three different types of laser welding: conduction, keyhole, and wobbling.

Welding is usually used on metals and thermoplastics, but it can also be used on wood. The completed welded joint may be referred to as a weldment. Some of the fields of application are naval, automotive and aerospace.

Welding

Lasers play a significant role in welding by providing precise, clean, and strong joints between materials. The most common types of lasers used for welding include fiber lasers, CO2 lasers, and diode lasers, each with specific strengths suited to different materials and applications.

Fiber lasers are particularly popular in welding due to their exceptional beam quality, high power density, and ability to focus on fine details. They are highly effective for welding metals such as stainless steel, aluminum, and titanium. Fiber lasers offer high-speed welding and deep penetration, making them ideal for applications where precision and speed are critical, like in the automotive and electronics industries. Their fast processing time and ability to handle both thin and thicker materials efficiently have made them a go-to for modern welding applications.

CO2 lasers, on the other hand, are known for their high power output and deep penetration, making them ideal for welding thicker materials. These lasers are commonly used in industries that require strong, durable welds, such as aerospace, heavy manufacturing, and automotive. CO2 lasers can be effective on metals like steel, aluminum, and various alloys. While their beam quality may not be as high as fiber lasers, they remain a valuable choice for large-scale welding operations and applications requiring high energy.

Diode lasers are typically used for more localized, small-scale welding applications. They are energy-efficient and offer excellent control over heat input, making them well-suited for welding thin metals and plastics. Diode lasers are smaller and more compact than fiber or CO2 lasers, making them ideal for applications where space is limited or where energy consumption is a concern. They are commonly used in consumer electronics, medical devices, and other precision welding tasks.

The choice of laser for welding depends on several factors, including the material being welded, the thickness of the material, and the desired weld speed and strength. Fiber lasers are ideal for precision and speed, CO2 lasers excel in deep penetration and thick material welding, while diode lasers provide energy efficiency and precision for smaller-scale projects.

Lasers play a significant role in welding by providing precise, clean, and strong joints between materials. The most common types of lasers used for welding include fiber lasers, CO2 lasers, and diode lasers, each with specific strengths suited to different materials and applications.

Fiber lasers are particularly popular in welding due to their exceptional beam quality, high power density, and ability to focus on fine details. They are highly effective for welding metals such as stainless steel, aluminum, and titanium. Fiber lasers offer high-speed welding and deep penetration, making them ideal for applications where precision and speed are critical, like in the automotive and electronics industries. Their fast processing time and ability to handle both thin and thicker materials efficiently have made them a go-to for modern welding applications.

CO2 lasers, on the other hand, are known for their high power output and deep penetration, making them ideal for welding thicker materials. These lasers are commonly used in industries that require strong, durable welds, such as aerospace, heavy manufacturing, and automotive. CO2 lasers can be effective on metals like steel, aluminum, and various alloys. While their beam quality may not be as high as fiber lasers, they remain a valuable choice for large-scale welding operations and applications requiring high energy.

Diode lasers are typically used for more localized, small-scale welding applications. They are energy-efficient and offer excellent control over heat input, making them well-suited for welding thin metals and plastics. Diode lasers are smaller and more compact than fiber or CO2 lasers, making them ideal for applications where space is limited or where energy consumption is a concern. They are commonly used in consumer electronics, medical devices, and other precision welding tasks.

The choice of laser for welding depends on several factors, including the material being welded, the thickness of the material, and the desired weld speed and strength. Fiber lasers are ideal for precision and speed, CO2 lasers excel in deep penetration and thick material welding, while diode lasers provide energy efficiency and precision for smaller-scale projects.