Laser brazing involves the joining of two objects by adding external material heated by the laser. Brazing is different from welding because of the addition of supplementary material in the form of brazing wires.

This method's popularity is due to its durability (similar to that of welded seams) and the high aesthetic quality of the assembled components. Brazed welds made with the diode laser are characterized by their watertightness and their smooth surfaces.

This technology is used to bond galvanized steel sheets or aluminum alloy components, which are typically used in the automotive industry. Thanks to these factors, the joint is ready for painting, which reduces the amount of finishing work required afterwards.

Brazing

Laser brazing involves the joining of two objects by adding external material heated by the laser. Brazing is different from welding because of the addition of supplementary material in the form of brazing wires.

This method's popularity is due to its durability (similar to that of welded seams) and the high aesthetic quality of the assembled components. Brazed welds made with the diode laser are characterized by their watertightness and their smooth surfaces.

This technology is used to bond galvanized steel sheets or aluminum alloy components, which are typically used in the automotive industry. Thanks to these factors, the joint is ready for painting, which reduces the amount of finishing work required afterwards.

Brazing

Lasers are increasingly used in brazing due to their ability to provide precise, controlled heat for joining metal parts with minimal thermal distortion. The most common types of lasers used for brazing are fiber lasers, CO2 lasers, and diode lasers, each offering unique advantages depending on the application.

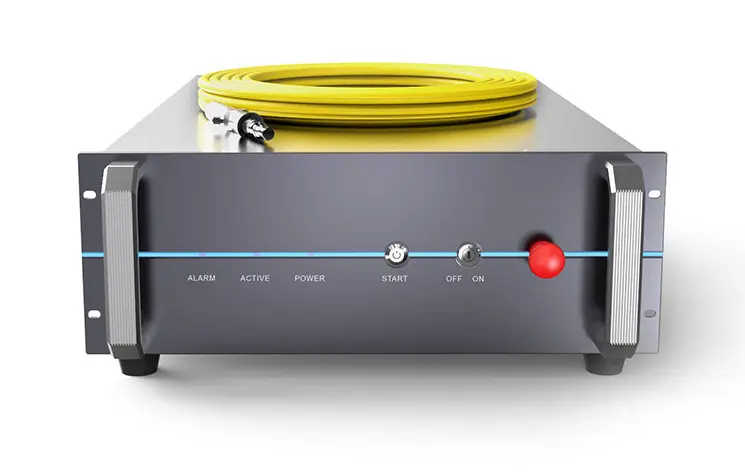

Fiber lasers are widely favored in brazing due to their excellent beam quality and high power density. They can focus on very small areas with great precision, making them ideal for applications in industries such as automotive and aerospace, where high-quality, clean joints are required. The ability of fiber lasers to deliver precise, localized heat allows for effective joining without affecting the surrounding material.

CO2 lasers are also commonly used in brazing, especially for materials that require deep penetration. These lasers can melt the filler material efficiently, ensuring strong, durable joints. With their high power output, CO2 lasers are capable of quickly heating the material, which is essential in industrial applications where speed and efficiency are critical.

Diode lasers offer another option for brazing, particularly in small-scale or highly localized applications. Known for their energy efficiency, diode lasers provide precise control of heat, which makes them suitable for applications requiring minimal distortion and a high degree of accuracy.

Lasers are increasingly used in brazing due to their ability to provide precise, controlled heat for joining metal parts with minimal thermal distortion. The most common types of lasers used for brazing are fiber lasers, CO2 lasers, and diode lasers, each offering unique advantages depending on the application.

Fiber lasers are widely favored in brazing due to their excellent beam quality and high power density. They can focus on very small areas with great precision, making them ideal for applications in industries such as automotive and aerospace, where high-quality, clean joints are required. The ability of fiber lasers to deliver precise, localized heat allows for effective joining without affecting the surrounding material.

CO2 lasers are also commonly used in brazing, especially for materials that require deep penetration. These lasers can melt the filler material efficiently, ensuring strong, durable joints. With their high power output, CO2 lasers are capable of quickly heating the material, which is essential in industrial applications where speed and efficiency are critical.

Diode lasers offer another option for brazing, particularly in small-scale or highly localized applications. Known for their energy efficiency, diode lasers provide precise control of heat, which makes them suitable for applications requiring minimal distortion and a high degree of accuracy.