Product Description

Handheld laser welding machines are a versatile tool that can be used in a wide range of industrial applications. It uses high-powered fiber lasers to fuse metals together, creating strong, durable welds that are resistant.

1. Precision welding: Handheld laser welding machines are capable of welding even the most delicate and intricate parts with great precision. This makes them ideal for use in industries such as electronics, aerospace, and biomedical, where precision welding is critical.

2. High welding speeds: Laser welding machines can operate at very high speeds, allowing them to complete welding jobs quickly and efficiently. This can help to increase productivity and reduce production costs.

3. Non-contact welding: Unlike traditional welding methods, laser welding machines do not require physical contact between the welding tool and the metal being welded. This eliminates the risk of contamination, distortion, and damage to the material.

4. Low heat input: Laser welding machines produce very little heat compared to traditional welding methods. This means that they can be used to weld materials that are sensitive to heat, such as thin sheets of metal or plastic.

5. Welding of dissimilar materials: Laser welding machines can be used to weld different types of metals together, as well as metals to non-metallic materials. This makes them ideal for use in industries such as automotive manufacturing, where a wide range of materials are used in the production process.

6. Portable and easy to use: Handheld laser welding machines are designed to be lightweight and portable, making them easy to move around the workshop or manufacturing facility. They are also easy to use, with intuitive controls that allow operators to quickly set up and start welding.

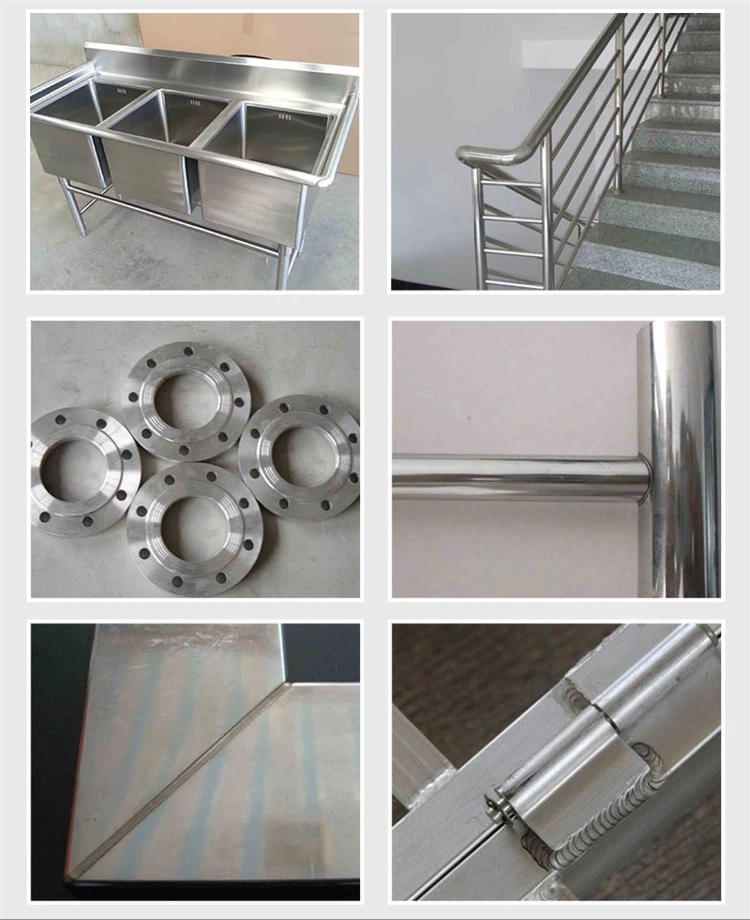

7. Versatile applications: Laser welding machines can be used in a wide range of applications, including repair work, prototyping, and production. They are especially useful for welding small parts and components, as well as for making repairs to existing welds.