Laser marking is a process in which a high-energy laser pulse, by removing or varying the properties of the treated material, leaves an indelible mark that is visible over time.

Depending on the material, the most optimal laser technology can be selected from a variety of wavelengths, pulse durations and working frequencies. This large choice enables the use of lasers in various applications like: traceability, barcode or QR code production, logo production, micro-structuring, rust removal or coating. Application fields are: automotive, pharmaceutical, packaging and electronics.

Marking

Laser marking is a process in which a high-energy laser pulse, by removing or varying the properties of the treated material, leaves an indelible mark that is visible over time.

Depending on the material, the most optimal laser technology can be selected from a variety of wavelengths, pulse durations and working frequencies. This large choice enables the use of lasers in various applications like: traceability, barcode or QR code production, logo production, micro-structuring, rust removal or coating. Application fields are: automotive, pharmaceutical, packaging and electronics.

Marking

Lasers are widely used in marking applications to create permanent, high-quality marks on various materials. The type of laser used depends on the material being marked and the specific requirements of the marking process. The most common types of lasers used for marking include fiber lasers, CO2 lasers and diode lasers.

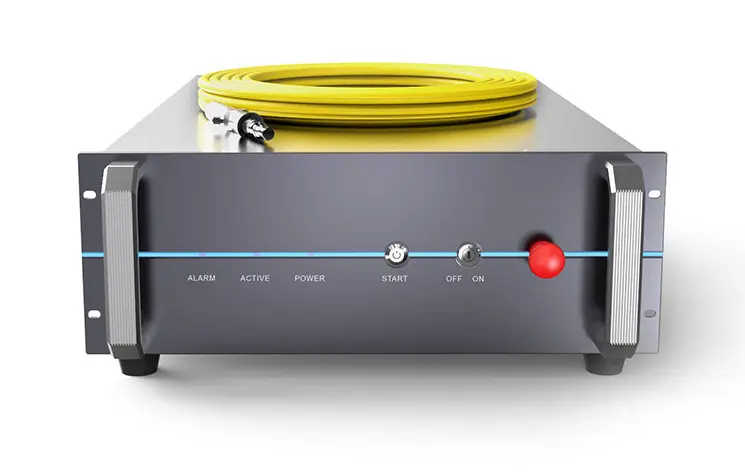

Fiber lasers are commonly used for marking metals, plastics, and other materials. They are known for their high beam quality and precision, allowing for deep engraving, fine line marking, and high-speed processing. Fiber lasers are particularly effective for marking metals such as stainless steel, aluminum, and titanium, as well as plastics. They are frequently used in industries like automotive, aerospace, and electronics for product identification, serial number engraving, and other marking needs.

CO2 lasers are versatile and effective for marking non-metal materials like plastics, wood, glass, and leather. They are ideal for creating smooth, precise marks with high contrast. CO2 lasers work by emitting infrared light, which is absorbed by the material, creating a clear, permanent mark. These lasers are commonly used for branding, engraving, and cutting in industries such as packaging, consumer goods, and woodworking.

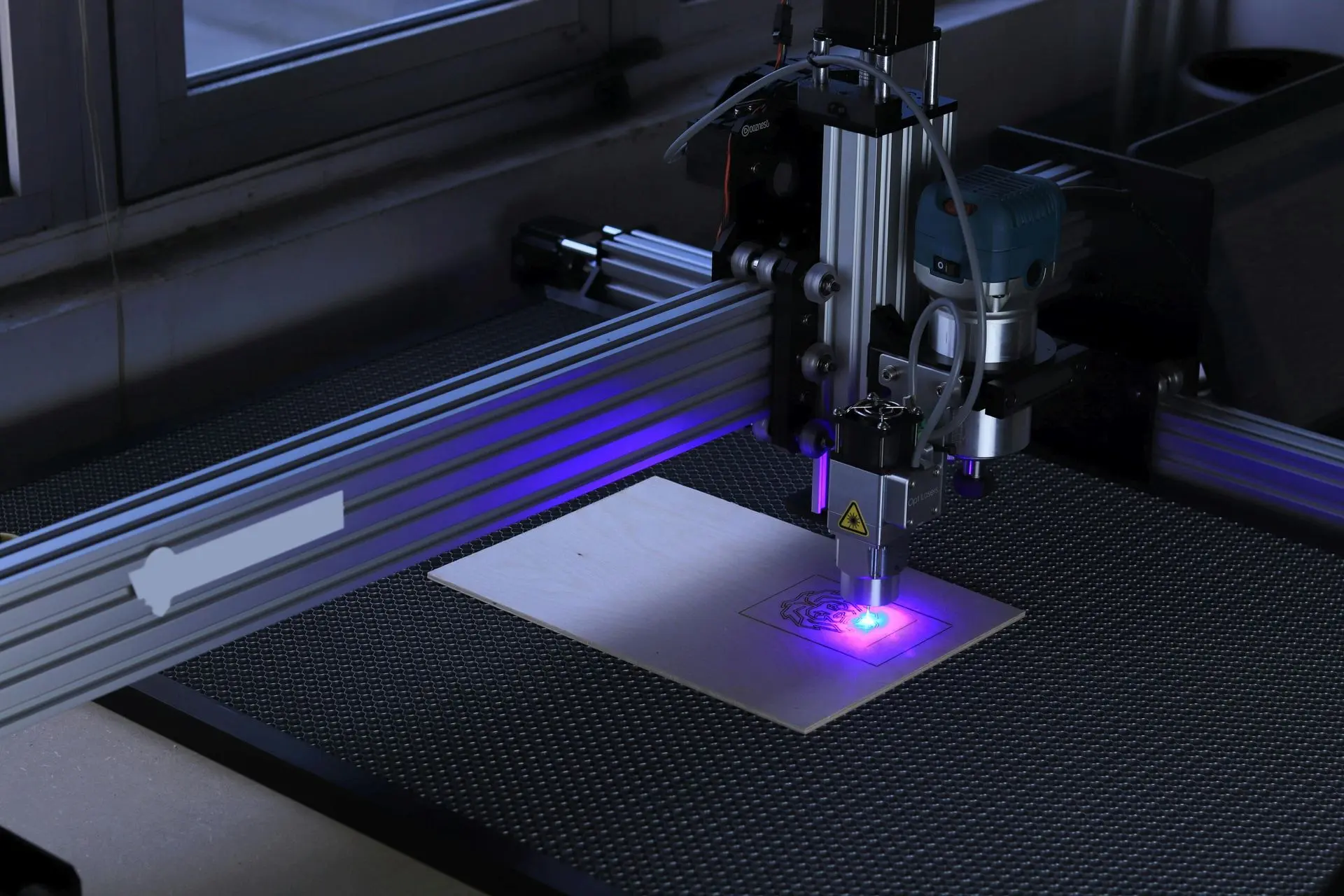

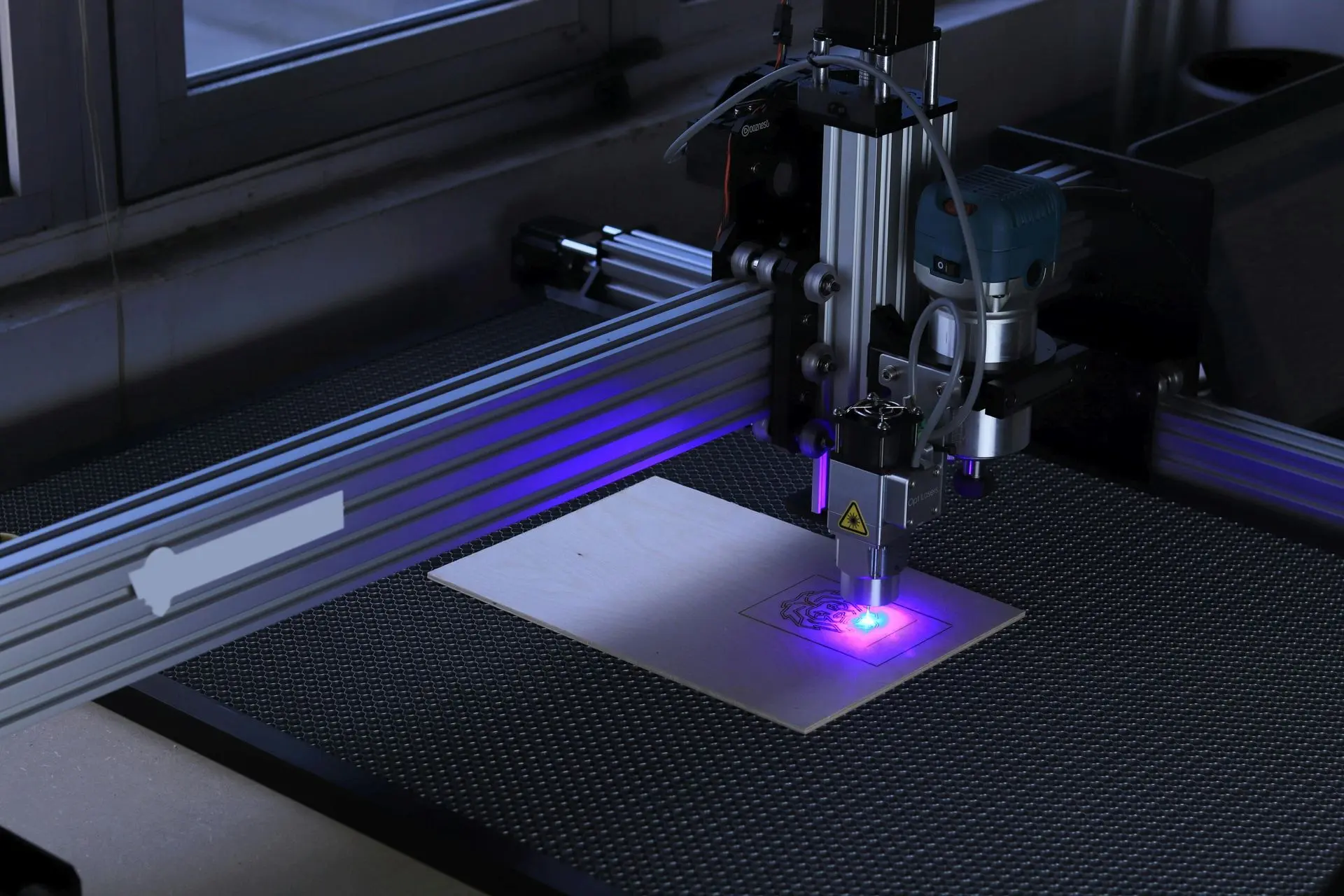

Diode lasers are often used for marking plastics, wood, and thin metals. These lasers are compact and energy-efficient, making them ideal for smaller marking systems and applications requiring minimal heat generation. Diode lasers are commonly used for barcode marking, QR code marking, and simple engravings in consumer goods, electronics, and packaging.

Each type of laser is selected based on the material being marked, the required depth of the mark, and the speed of the marking process. Fiber lasers are most commonly used for metal marking due to their precision and versatility, while CO2 and diode lasers are frequently used for non-metal materials due to their efficiency and cost-effectiveness.

Lasers are widely used in marking applications to create permanent, high-quality marks on various materials. The type of laser used depends on the material being marked and the specific requirements of the marking process. The most common types of lasers used for marking include fiber lasers, CO2 lasers and diode lasers.

Fiber lasers are commonly used for marking metals, plastics, and other materials. They are known for their high beam quality and precision, allowing for deep engraving, fine line marking, and high-speed processing. Fiber lasers are particularly effective for marking metals such as stainless steel, aluminum, and titanium, as well as plastics. They are frequently used in industries like automotive, aerospace, and electronics for product identification, serial number engraving, and other marking needs.

CO2 lasers are versatile and effective for marking non-metal materials like plastics, wood, glass, and leather. They are ideal for creating smooth, precise marks with high contrast. CO2 lasers work by emitting infrared light, which is absorbed by the material, creating a clear, permanent mark. These lasers are commonly used for branding, engraving, and cutting in industries such as packaging, consumer goods, and woodworking.

Diode lasers are often used for marking plastics, wood, and thin metals. These lasers are compact and energy-efficient, making them ideal for smaller marking systems and applications requiring minimal heat generation. Diode lasers are commonly used for barcode marking, QR code marking, and simple engravings in consumer goods, electronics, and packaging.

Each type of laser is selected based on the material being marked, the required depth of the mark, and the speed of the marking process. Fiber lasers are most commonly used for metal marking due to their precision and versatility, while CO2 and diode lasers are frequently used for non-metal materials due to their efficiency and cost-effectiveness.